Our Story

MasterCap started headwear business from 1997, at the early stage, we focused on processing with supplied material from other big headwear company in China. In 2006, we built our own sales team and sold well to both oversea and domestic market.

After more than twenty years’ development, MasterCap we have built 3 production bases, with more than 200 employees. Our product enjoy high reputation for its excellent performance, reliable quality and reasonable price. We sell our own brand MasterCap and Vougue Look in domestic market.

We offer wide range of quality caps, hats and knit beanies in the sports, streetwear, action sports, golf, outdoor and retail markets. We provide design, R&D, manufacturing and shipping based on OEM and ODM services.

We build cap for YOUR BRAND.

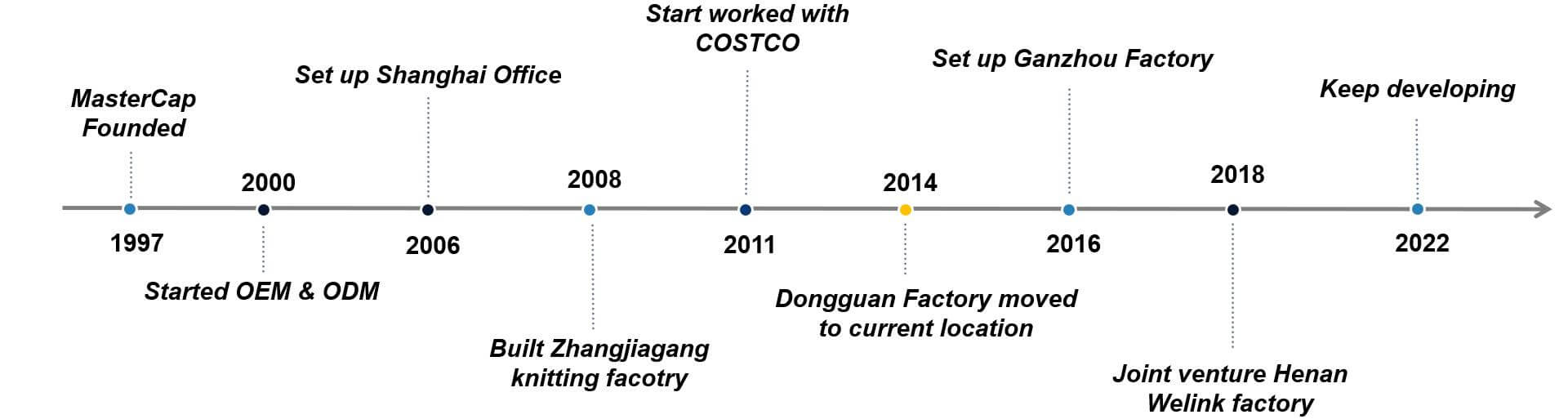

Our History

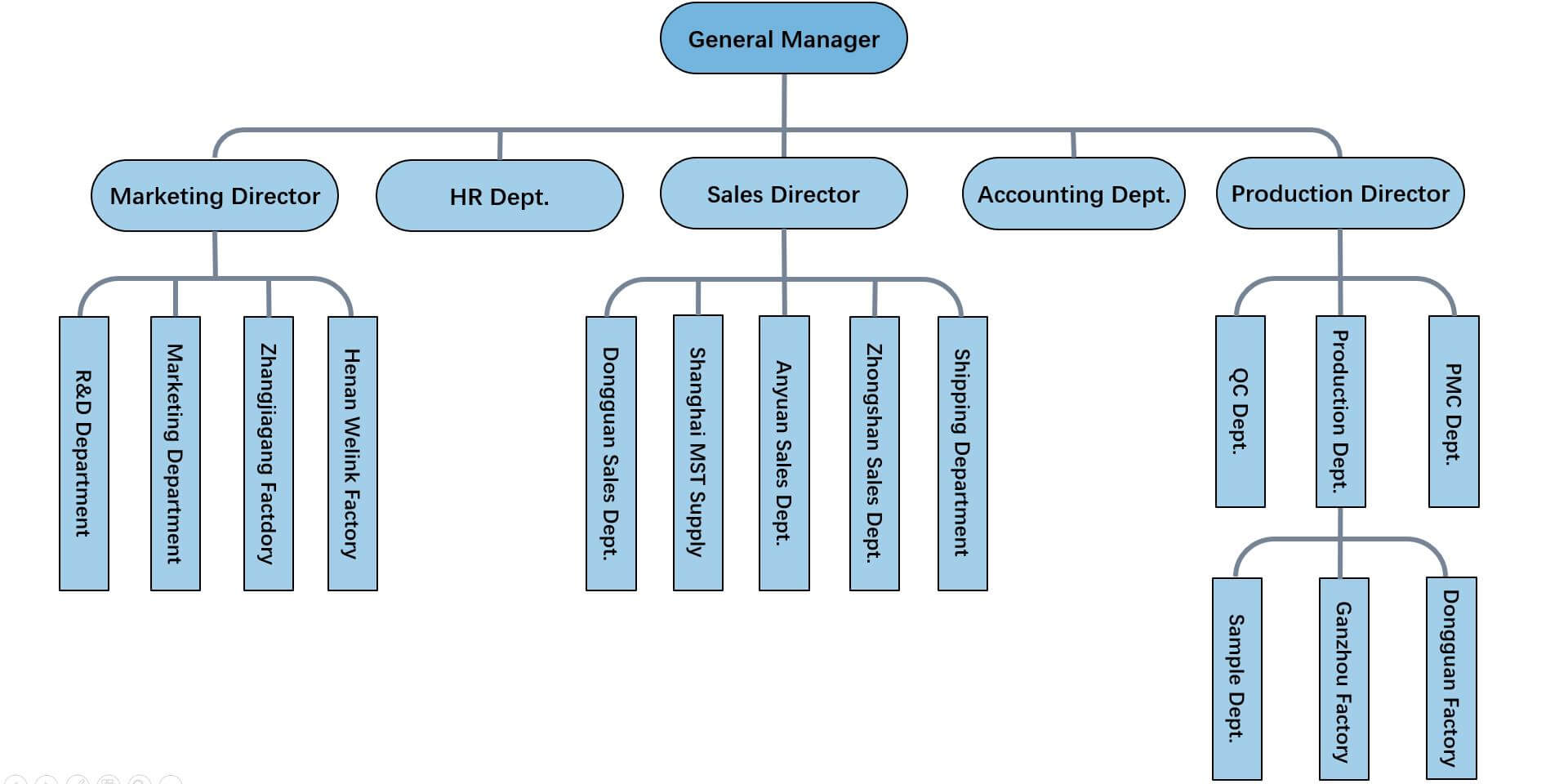

Company Structure

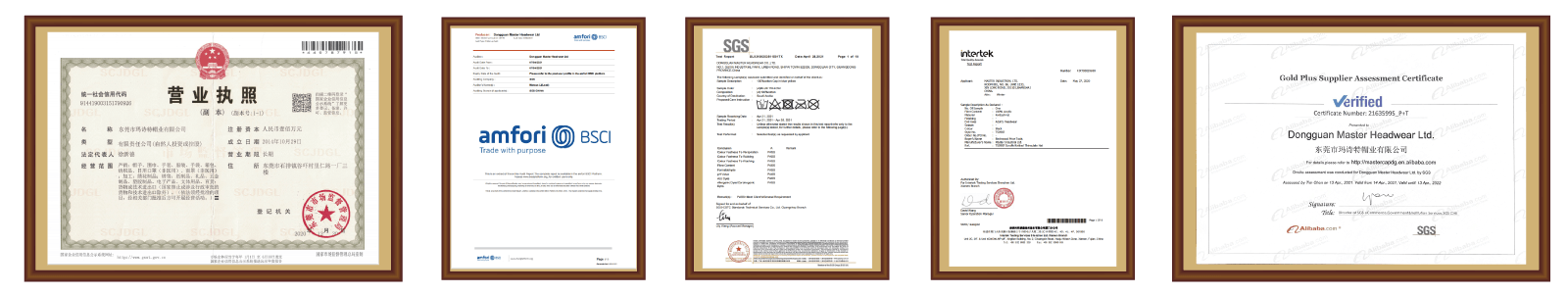

Certificates

Our Facilities

Dongguan Factory

Factory Building

Sales Office

Show Room

Cutting Room

Sewing Workshop

Cap Ironing

Fabric Warehouse

Products Warehouse

Shanghai Office

Office Building

Sales Office

Show Room

Jiangxi Factory

Workshop

Meeting Room

Factory Office

Zhangjiagang Knitting Factory

Factory Building

Workshop

Packing Department

Henan Welink Sportswear Factory

Factory Building

Workshop

Embroidery Department

Our Team

Team Leader

Our Team

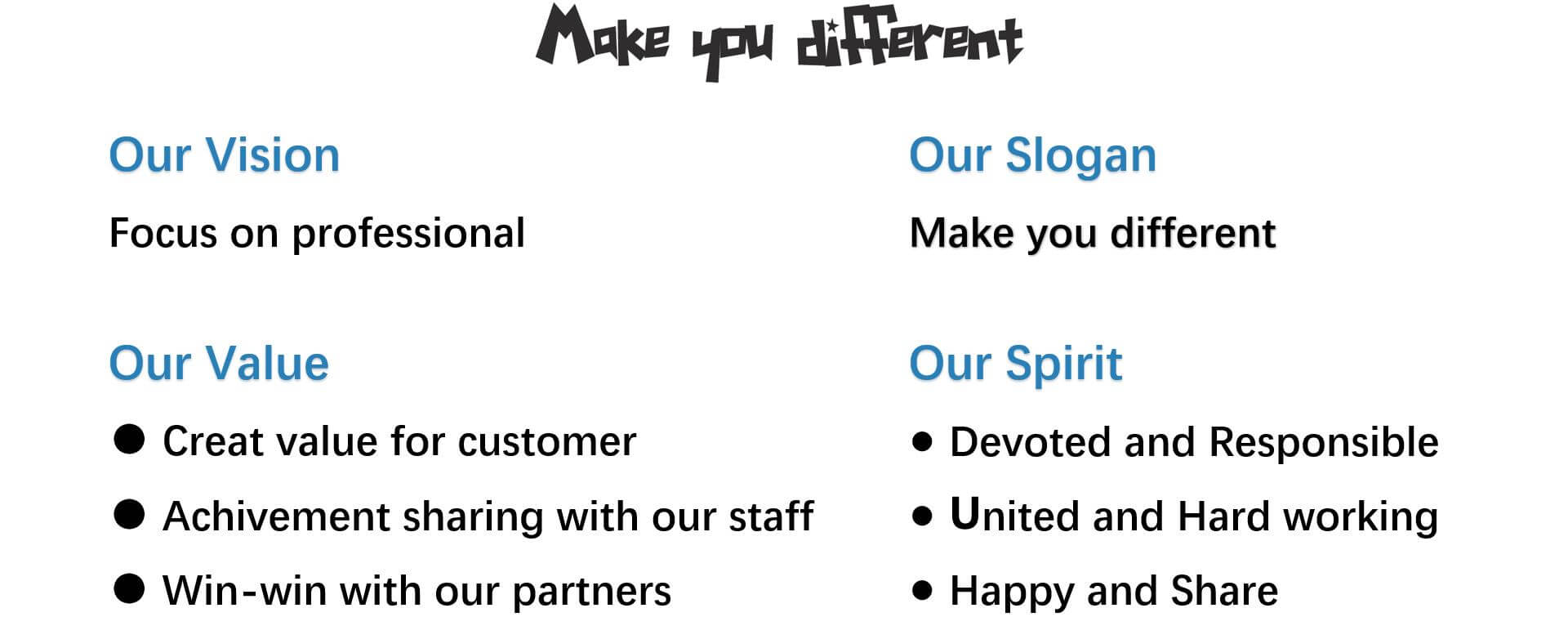

Our Culture

Our Brands

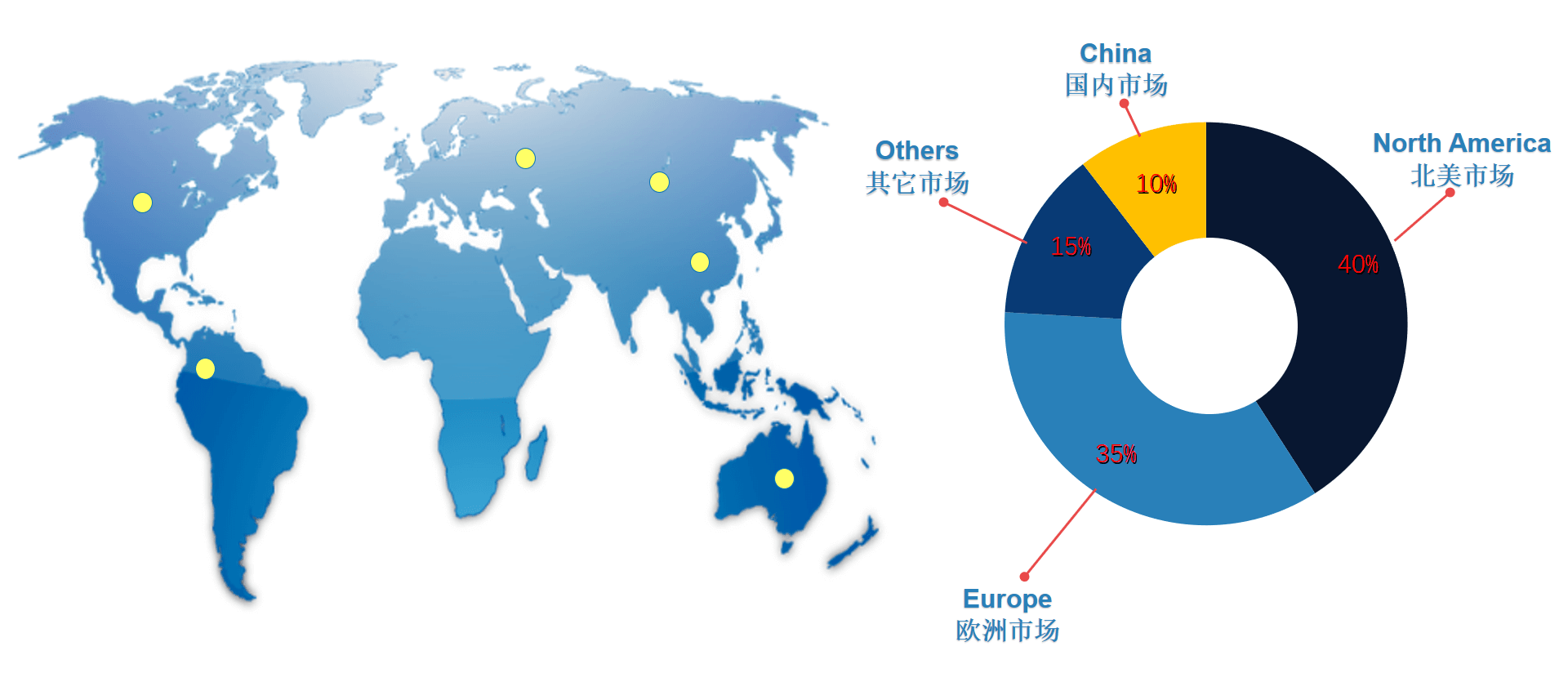

Our Market

Our Partners

Our Clients

Project Cases

Caps

Hats

Knit Beanies

Other Styles

Other Items

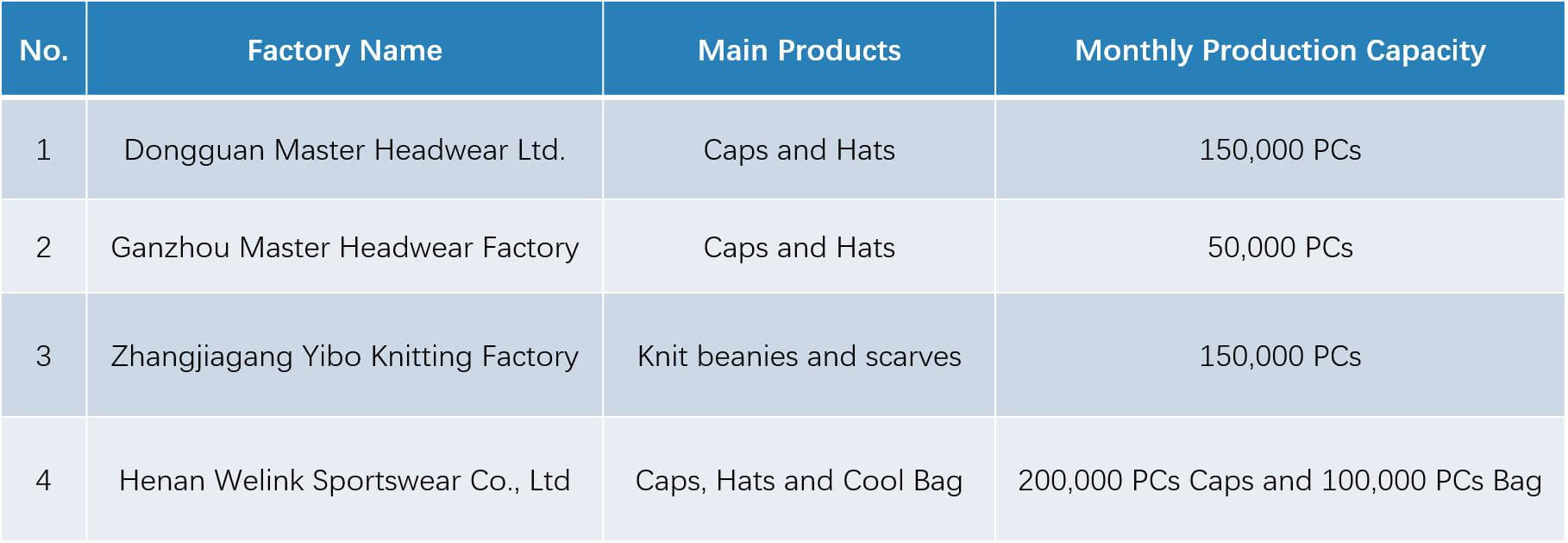

Our Capacity

Quality Control

- QC.

No products will be released before QC checking. Strict QC procedures are conducted in all working processes, from materials to finished products.

- Qualified Materials

All materials sourced from qualified suppliers,do test for material according to client’s requirements.

- QC Procedures

From material inspection, in-line inspection, final inspection and technical support. With specialized personnel, instruments and equipment.

- Quality Guaranteed

We guarantee the quality.

Research and Development

- R&D Staff

We have 10 staffs in our R&D Team, including the designer, paper pattern makers, technician, skilled sewing worker.

- Equipment for R&D

We keep up-to-date with modern equipment. Advanced technology is used to create your custom designs, we provide OEM and ODM service.

- Design and Styles

We develop more than 500 new styles every month to satisfy changing market demands. We have same model as mainstream cap styles and cap shapes in the world.

Services and Support

- Sample Availability & Policy.

Sample fee depends on from deisgn to design. Normally express freight and taxes will be collected.

- Guarantees Terms and Conditions

We insist on keeping our customers well informed on sample and order status. The products are quality-guaranteed

- Export/Import Processing Support

We provide good sales services, such as shipping, insurance, customs clearance, export documents and more. We are always willing to serve your requests.

- After Sales Service

We listen to client’s suggestion or complaint. Any suggestion or complaint will be responded within 8 hours.

Code OF Conduct

- Equal Employment Opportunity

We provide employees with a working environment free of discrimination, harassment, intimidation or coercion relating directly or indirectly to race, religion, sexual orientation, political opinion or disability.

- Health and Safety Working Environment

We maintain a safe, clean and healthy working environment in compliance with all applicable laws and regulations.

- No child labor and no slave labor

Our working hours and overtime comply with local labour law. No child labor and no slave labor.

- Concern for the Environment

We believe it is our duty to protect the environment and we do this by complying with all applicable environmental laws and regulations.

Social Responsibility

- No environment pollution allowed from fabric dyeing to products finished. We believe it is our duty to protect the environment and we do this by complying with all applicable environmental laws and regulations.

- Committed to providing immediate and long-term support for education or those affected by natural disasters, we ensure continuous improvement of their learning, living and learning conditions.

Why Choose US?

Fast Respond

Professional, patient, focused, react and take action within 8 hours

Small MOQ

Low MOQ with full custom design

Factory Audit

Supporting great brand’s factory audit by BSCI Certified

Professional and Focus

Super team ensure smooth running from development to shipment

High Quality

Strict QC procedures are conducted in all working processes from material to finished products

Powerful R&D

500+ new styles to be created every month for market demands, based on OEM and ODM service

Our Video

Global Buyer’s Pain Points

It can be extremely daunting trying to negotiate complex business issues when communication is so difficult.

For example your supplier’s samples totally different with what you’ve confirmed,or the mass production packing details not exactly same as it in your contract.

And even worse the Logo print on the hat ribbon are wrong for your mass production order… All of those are because of lacking communication during the job processing.

To get around this problem,customer can always ask our contacts for the skype /whatsapp number and chat online.

We are more than happy to talk with our customer in case of urgent things and to be solved instantly.Also an email will be sent as a record after online talking.

Unreasonable price raising is really a headache and will lose your sleep after you sign a contract with a supplier .

Because everything confirmed and your profit also be locked at such percentage,however the supplier come to ask for a price rising .

And for us as we are always considering long term relatioship with our customer,so we will never request a unreasonable price-raising with our customer.

Low quality issue including Cosmetic defects,Damaged items,Wrong colour/size,Functional defective items,Substandard material or components,Transportation damages,Substandard packaging for the products etc.

These issues on quality mainly come with 2 causes :

Cause A – Misunderstanding between the supplier and the customer

Cause B – The supplier is cheating the importer quality

As state in the point 1 if the importer choose a trustworthy supplier like us do well in communicating ,then these quality issue will be not existing.

Almost customers have their schedule on the goods importing from China,always the preparing time is 2-3 months.That means 80-90 days before they are preparing to contact the supplier for the coming orders .Even if the order is in a big volume scale then 2-3 months maybe not enough.There 2 main factors maybe lead to a delay of shipment :

Factor A – Without communication and careful following-up schedule ,the supplier can not finish the products on time.

Factor B – Even the products finished on time,but they are not familiar with the export procedure and they don’t know how to do the paperwork with customer assigned forwarder,for example they forgot to book the vessel space one week before ETD with the forwarder,they forgot to send ISF(Import Security Filing) to the CNEE and confirm with CNEE 48 hours before the ETD .

So when you are working with us ,these problems will be disappeared based on our strict following-up schedule and experienced team rendering in this area more than 10 years.

Sample was confirmed in a high standard of quality, but for bulk it turns to be significant different than those samples, why this happen, most of this issue comes from lack of experiences from the sales team when communicate with the buyer, for samples the client demand on a high standard, the sales want to get the order and arrange sample in a high standard, but they did not considering the bulk production. Which will totally make orders fail in the end, even probably the sampling is successful in some way.

For a custom order need to wait till 45-60days? It is too late Especially there is event scheduled.

Our Work Flow

When customer dont have a finished drawings,Only with the initial idea and artwork our factory engineers can help customer make graphic mock-ups with your logo, these mock-up also evaluated by our plant production manager so as to check its possibilities for production,then we send these images or drawings to customer for approval.

If customer provide finished drawings, then we will have the plant production manager check the drawings for technical feasibility,if required modification our designer will adjust them in consultation with you.

If customer need a customized size of hat so we have to set-up new hat molding . it always take 2-3 weeks on the complexity of the tooling.Then customer can choose the color of the hat and ribbon ,so we will start sampling accordingly.Always take 6-7 days for a pre-production sample.

After our sampling room finished the first set of products which made from the new mold are the pre-production samples (PPS). Our QC will check them thoroughly, and after that we will send you 1-2 PPS for approval. We are glad to receive your feedback once you have received the pre-production sample.If some minor changes are required,we will inform the factory and they will produce new pre-production samples. Minimal running changes could also be done at the beginning of mass production and our QC team will check these on the production samples or with an in-line inspection.

After sample approval and order confirmation,our production line will start to production as the previous critical schedule which we confirmed with customer. Once production started there is a production flow chart will be used for every step of production from the material preparing to the end of production finished. The production flow chart just like this one below

For each order, a final inspection takes place after production is finished. We are proud to say that we work with the general inspection level II during our final inspection. This makes our standard AQL values as 0 for critical defects, 1.0 for major defects and 2.5 for minor defects.

Level II inspection levels are typically used for retail goods, and therefore it is a more stringent standard than the one typically used for promotional products (0 for critical, 2.5 for major and 4.0 for minor defects). We take this more stringent approach to inspection because we value getting things right the first time around.

For higher quantity orders Our QC personnel carries out one (or more) in-line inspections in addition to the evaluation of production samples and final inspections to ensure production quality standards are being met.

Usually our products will be delivered to North America by ocean freight. The delivery time is approx. 30 – 40 days including customs clearance and transport in North America. Of course we offer other options for smaller quantities or very urgent projects.

You can choose between air freight, Express service like DHL,FedEx,UPS and TNT. The delivery time is between 2 – 10 days including customs clearance and transport in North America. Customs clearance is handled by our specialized service provider for you when the delivery option DDP is chosen, and the goods will be delivered to your door or to your customer’s warehouse.